Are you looking to bend steel sheet at home but don’t know where to start? Bending steel might seem like a job for big workshops, but with the right tips and tools, you can do it yourself.

Imagine saving time and money by shaping steel exactly how you want it, right in your own space. In this guide, you’ll discover simple steps that make bending steel easy and safe. Keep reading, and you’ll gain the confidence to take on your next steel project like a pro.

Credit: www.eastwood.com

Tools Needed For Bending Steel

Bending steel sheet at home requires the right tools. These tools help you shape the metal safely and correctly.

Some tools are essential hand tools you must have. Others are optional power tools that make the job easier. Safety gear is also important to protect yourself.

Essential Hand Tools

Hand tools allow you to bend steel with control and precision. They are affordable and easy to use for small projects.

- Clamps to hold the steel sheet firmly in place

- Hammer for shaping and bending the metal

- Metal ruler or measuring tape for accurate measurements

- Marker or scribe to mark bend lines

- Metal bending brake or bending pliers for straight and curved bends

Optional Power Tools

Power tools save time and reduce effort when bending steel sheets. They are useful for thicker or larger metal pieces.

| Tool | Use |

| Angle Grinder | Cut steel before bending |

| Power Drill | Make holes or help with bending attachments |

| Sheet Metal Brake (Electric) | Make precise bends quickly |

| Heat Gun | Soften metal to bend easier |

Safety Gear

Protect yourself while bending steel. Safety gear prevents injuries and hazards.

- Safety goggles to protect your eyes from metal shards

- Heavy-duty gloves to avoid cuts and burns

- Long-sleeve clothing to shield your skin

- Ear protection if using loud power tools

- Dust mask to avoid inhaling metal dust

Choosing The Right Steel Sheet

Bending steel sheet at home needs a good choice of material. The right steel sheet makes the process easier and safer.

Consider the type, thickness, and surface finish before you start bending. These factors affect the result and tools needed.

Types Of Steel Sheets

Steel sheets come in many types. Mild steel is soft and easy to bend. Stainless steel is strong and resists rust but is harder to shape. Galvanized steel has a zinc coating that protects against corrosion.

- Mild Steel: Easy to work with, ideal for beginners.

- Stainless Steel: Durable, needs more force to bend.

- Galvanized Steel: Corrosion-resistant, coated with zinc.

Thickness Considerations

The thickness of the steel sheet changes how hard it is to bend. Thin sheets bend easily but can wrinkle. Thick sheets need more power and strong tools.

| Thickness (inches) | Bending Difficulty | Recommended Tools |

| 0.01 – 0.04 | Easy | Hand tools, pliers |

| 0.05 – 0.12 | Moderate | Clamps, bending brake |

| 0.13 and above | Hard | Heavy-duty brake, power tools |

Surface Finishes

Surface finishes protect steel sheets and change their look. Some finishes make bending tricky. Choose finishes that suit your project and tools.

- Mill Finish: Raw steel, easier to bend but may rust.

- Painted: Adds color and protection, can crack when bent.

- Galvanized: Zinc layer protects from rust, needs care when bending.

Preparing The Steel Sheet

Bending a steel sheet at home needs proper preparation. Careful steps help you get clean, precise bends without damage.

First, prepare your steel sheet by measuring, marking, cleaning, and setting up a safe work area. These tasks make bending easier and safer.

Measuring And Marking

Accurate measuring and marking guide your bends. Use clear marks to avoid mistakes and get straight bends.

- Use a steel ruler or tape measure for accuracy

- Mark bend lines with a fine-tip permanent marker or scribe

- Double-check measurements before marking

- Mark both sides of the sheet if possible

- Use a square tool to keep lines straight

Cleaning The Surface

Clean the steel sheet to remove dirt, oil, and rust. A clean surface helps prevent scratches and improves bending quality.

| Cleaning Task | Tools Needed | Purpose |

| Remove dirt and dust | Soft cloth, mild detergent | Clear surface for marking |

| Remove oil and grease | Degreaser or rubbing alcohol | Prevent slipping during bending |

| Remove rust spots | Wire brush or sandpaper | Ensure smooth bending edges |

| Dry the surface | Clean dry cloth | Avoid moisture damage |

Setting Up A Work Area

Organize a safe, stable workspace before bending steel. A good setup prevents accidents and helps keep your tools ready.

Follow these guidelines:

- Work on a flat, sturdy surface like a workbench or thick table

- Use clamps to hold the steel sheet firmly in place

- Keep your tools within easy reach

- Wear safety gear: gloves, goggles, and closed shoes

- Ensure good lighting to see markings clearly

Bending Techniques

Bending steel sheets at home can be challenging but rewarding. Different techniques can help you achieve the desired bends.

Each method has its own benefits. Choose the one that suits your tools and the thickness of the steel sheet.

Manual Bending Methods

Manual bending is simple and requires no special tools. It uses basic tools you may already have.

- Use a sturdy table edge for support.

- Bend by hand while applying steady pressure.

- Use clamps to hold the sheet in place.

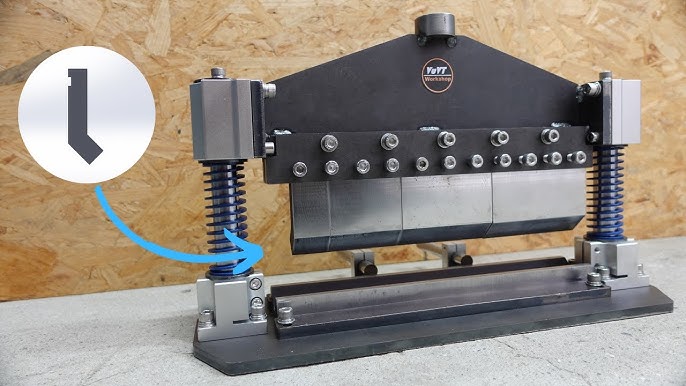

Using A Brake Or Clamp

A brake or clamp gives more control over the bend. It is ideal for straight and precise bends.

Heating For Easier Bends

Heating the steel sheet makes bending easier. It reduces the force needed to create bends.

| Tool | Use |

| Blowtorch | Evenly heat the bend area |

| Oven | Heat the entire sheet for uniformity |

| Heat Gun | Best for small sections |

Tips For Achieving Clean Bends

Bending steel sheets at home can be tricky. Clean bends make your project look professional and last longer.

Using the right tools and techniques helps you avoid damage and get perfect results every time.

Avoiding Cracks And Deformation

Steel can crack or deform if bent too fast or with too much force. Take your time and apply steady pressure.

Use a soft material like wood or rubber as a backing to protect the steel surface during bending.

- Heat the steel slightly to reduce cracking risk

- Use a bending brake or clamps to hold the sheet

- Bend slowly and evenly along the line

Maintaining Angle Accuracy

Mark your bend line clearly before starting. Use a protractor or angle guide to check the bend angle.

Make small adjustments and check the angle often to keep it accurate throughout the process.

- Draw bend lines with a permanent marker

- Use a square or angle finder tool for precision

- Test bends on scrap metal before working on your piece

Handling Springback

Springback happens when the steel tries to return to its original shape after bending. Expect a small angle change.

Bend the steel slightly beyond the target angle to account for springback and get the correct final shape.

- Know the steel type and thickness to estimate springback

- Make test bends and measure the springback effect

- Adjust your bending angle accordingly

Credit: www.youtube.com

Finishing Touches

After bending steel sheets at home, finishing touches make your work safe and strong. These steps improve the look and durability of the bent steel.

Focus on smoothing edges, checking the bend quality, and applying protective coatings for the best results.

Smoothing Edges

Steel edges can be sharp and dangerous after bending. Use a file or sandpaper to smooth them. This step helps prevent cuts and gives a clean finish.

- Wear gloves before handling edges

- Use medium grit sandpaper to remove burrs

- Finish with fine grit for a smooth touch

- Clean dust with a dry cloth

Checking Bend Quality

Check your steel bend to ensure it meets your project needs. Look for cracks, uneven angles, and proper alignment. Use a ruler and protractor for accuracy.

| Check Point | What to Look For |

| Cracks | No visible breaks or splits |

| Angle | Matches desired bend angle |

| Edges | Even and smooth, no sharp points |

| Surface | No dents or warping |

Applying Protective Coatings

Protect the steel sheet from rust and damage by applying coatings. Choose paint, oil, or a sealant based on your steel type and use.

Follow this simple guide for coating:

- Clean the steel surface thoroughly.

- Apply a thin, even layer of your chosen coating.

- Allow it to dry completely.

- Apply a second layer if needed for extra protection.

Common Mistakes To Avoid

Bending steel sheets at home can be tricky. Many people make avoidable mistakes. This guide helps you prevent them.

Let’s look at common errors. Avoid these to ensure safety and accuracy when bending steel sheets.

Overbending Or Underbending

Getting the right bend angle is crucial. Overbending or underbending can ruin your project. Measure twice to ensure accuracy.

| Issue | Result |

| Overbending | Weakens the metal |

| Underbending | Parts do not fit |

Ignoring Safety Precautions

Safety is vital when bending steel. Ignoring safety measures can cause injury. Always wear protective gear.

- Wear gloves to protect your hands

- Use safety goggles to shield your eyes

- Keep your workspace organized

Using Wrong Tools

Using the wrong tools can lead to poor results. Always select the right tool for your task. This improves efficiency and safety.

For example, a bench vise is great for small bends, while a sheet metal brake is better for larger projects.

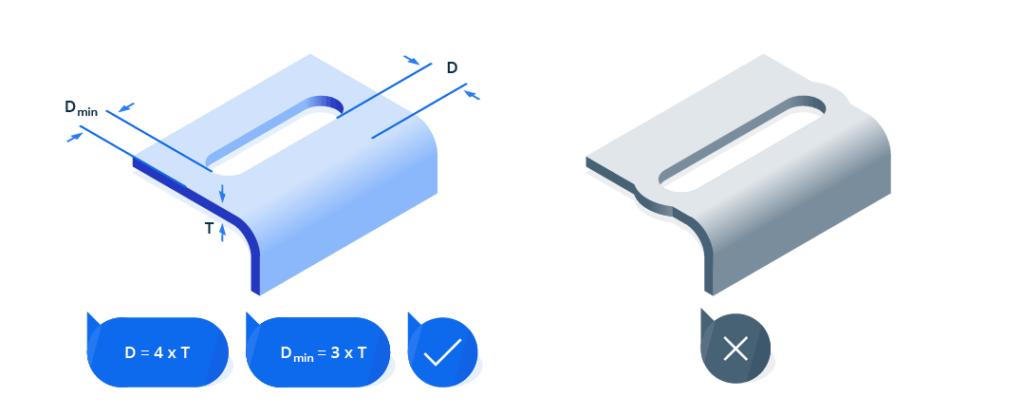

Credit: xometry.pro

Frequently Asked Questions

How Do I Bend Steel Sheet Without Professional Tools?

You can bend steel sheets at home using clamps, a sturdy workbench, and a hammer. Heat the steel with a propane torch for easier bending. Always wear safety gear like gloves and goggles to protect yourself during the process.

What Thickness Of Steel Sheet Can I Bend At Home?

Sheets up to 16 gauge (about 1. 5 mm thick) are easier to bend at home. Thicker sheets require specialized tools or heat treatment. Using heat softens the metal, making bending manageable for most DIY projects.

How Can I Prevent Steel Sheet From Cracking When Bending?

To prevent cracking, heat the steel sheet evenly before bending. Bend slowly and steadily to avoid stress points. Use a bending brake or form a radius instead of a sharp angle for smoother bends.

What Safety Precautions Are Needed When Bending Steel Sheets?

Always wear gloves, safety goggles, and long sleeves to protect against sharp edges and sparks. Work in a well-ventilated area when using heat. Secure the steel firmly to avoid slips and injuries during bending.

Conclusion

Bending steel sheets at home is doable with the right tools. Start with careful measuring and marking. Use steady pressure to avoid cracks or bends. Practice on scrap pieces to build confidence. Safety matters—always wear gloves and eye protection. Simple steps lead to strong, clean bends.

Keep patience and work slowly for best results. This skill saves money and adds value to projects. Try it yourself and see the difference.